Struggling to make your chocolates stand out? Poor packaging can make a premium product look cheap. A beautiful bag boosts appeal and justifies a higher price point for your brand.

OPP block bottom bags1 are ideal for chocolates because their high clarity showcases the product beautifully. Their flat, stable base allows them to stand upright on shelves for an excellent presentation, and they offer great moisture protection2 to maintain freshness and quality, protecting your investment.

The first time I saw a block bottom bag, I was struck by how it turned a simple product into a small gift. It just looked more valuable on the shelf. But getting it right, especially with a material like OPP, is more complex than it looks. This complexity is where the real value lies, for both the product and your business. To really understand why these bags are perfect for chocolates, we first need to break down the material itself. It’s crucial to know the details when you're making a purchasing decision.

Is OPP the same as PP?

Confused by all the plastic acronyms? Choosing the wrong material can lead to packaging that fails to protect or present your product properly. Let me clarify the difference for you.

No, OPP is not identical to PP. OPP stands for Oriented Polypropylene3, which is a specific type of PP (Polypropylene). OPP film is stretched, making it much clearer, stronger, and more rigid than standard, non-oriented PP. Think of it as an enhanced version of PP.

When I first started in this industry, I thought all "PP" was the same. A client wanted bags for hard candy and specified "PP." We made bags from standard PP, and they looked cloudy and felt flimsy. The client was unhappy. That's when I learned the hard way about the difference orientation makes. The "O" in OPP is critical. It refers to the manufacturing process where we stretch the PP film. This stretching aligns the plastic molecules, which dramatically changes the material's properties. We call this biaxial orientation4. This single step transforms a basic polymer into a premium packaging material. For a product manager like you, knowing this difference is key to writing the correct specifications for your packaging supplier.

Understanding the Key Differences

Let's break down the practical differences that result from this orientation process.

| Property | Standard PP (Polypropylene) | OPP (Oriented Polypropylene) |

|---|---|---|

| Clarity | Translucent to hazy. | Crystal clear, high-gloss finish. |

| Rigidity | Flexible and soft. | Stiff and crisp. Creates a "crinkling" sound. |

| Strength | Good tensile strength5, but can tear easily once started. | Very high tensile strength, more puncture resistant. |

| Best For | Items where clarity is not critical, like textiles or bulk parts. | Premium products where visual appeal is key, like chocolates. |

What is a PP bag used for?

You see plastic bags everywhere, but which are PP? Using the wrong type means you could be overpaying or getting a bag that doesn't perform. Let's look at PP's best uses.

A standard PP (Polypropylene) bag is typically used for packaging items where high clarity isn't a priority. Its durability and low cost make it great for clothing, magazines, industrial parts, and some agricultural products that need a basic, protective covering rather than a premium presentation.

Standard PP is the workhorse of the industry. It’s reliable and cost-effective. A friend of mine runs a small online business selling custom t-shirts. He uses simple PP bags. Why? They protect the shirts from dust and dirt during shipping, they are inexpensive, and his customers are focused on the product inside, not the bag. The bag just needs to do its job, which is protection. For him, using a high-clarity OPP bag would be an unnecessary expense. This is a perfect example of matching the packaging to the product's needs and the customer's expectations. You don't always need the premium option. Sometimes, good and economical is the smartest choice for your supply chain.

Matching PP Bags to Products

Choosing the right bag comes down to balancing cost, protection, and presentation. Standard PP bags excel in specific areas.

Industrial and Bulk Goods

In a factory setting, you need packaging that is tough and cheap. PP bags are perfect for holding small hardware like screws, nuts, and bolts. They prevent parts from getting lost and protect them from moisture. For bulk agricultural goods like animal feed or seeds, large woven PP sacks are used because they are strong enough to hold heavy weights and resist tearing during transport.

Soft Goods and Print Media

For products like clothing, the main goal is to keep the item clean until it reaches the customer. A simple PP bag does this perfectly. The slight haziness of the material is not a problem because the customer will remove it immediately. It's the same for bundling magazines or newspapers. The PP wrap protects them from the elements without adding significant cost. In these cases, the bag is purely functional.

Are polypropylene bags better than plastic bags?

"Plastic" is a very general term. This can cause confusion when trying to source sustainable or high-performance packaging. Let me explain where polypropylene fits in the world of plastics.

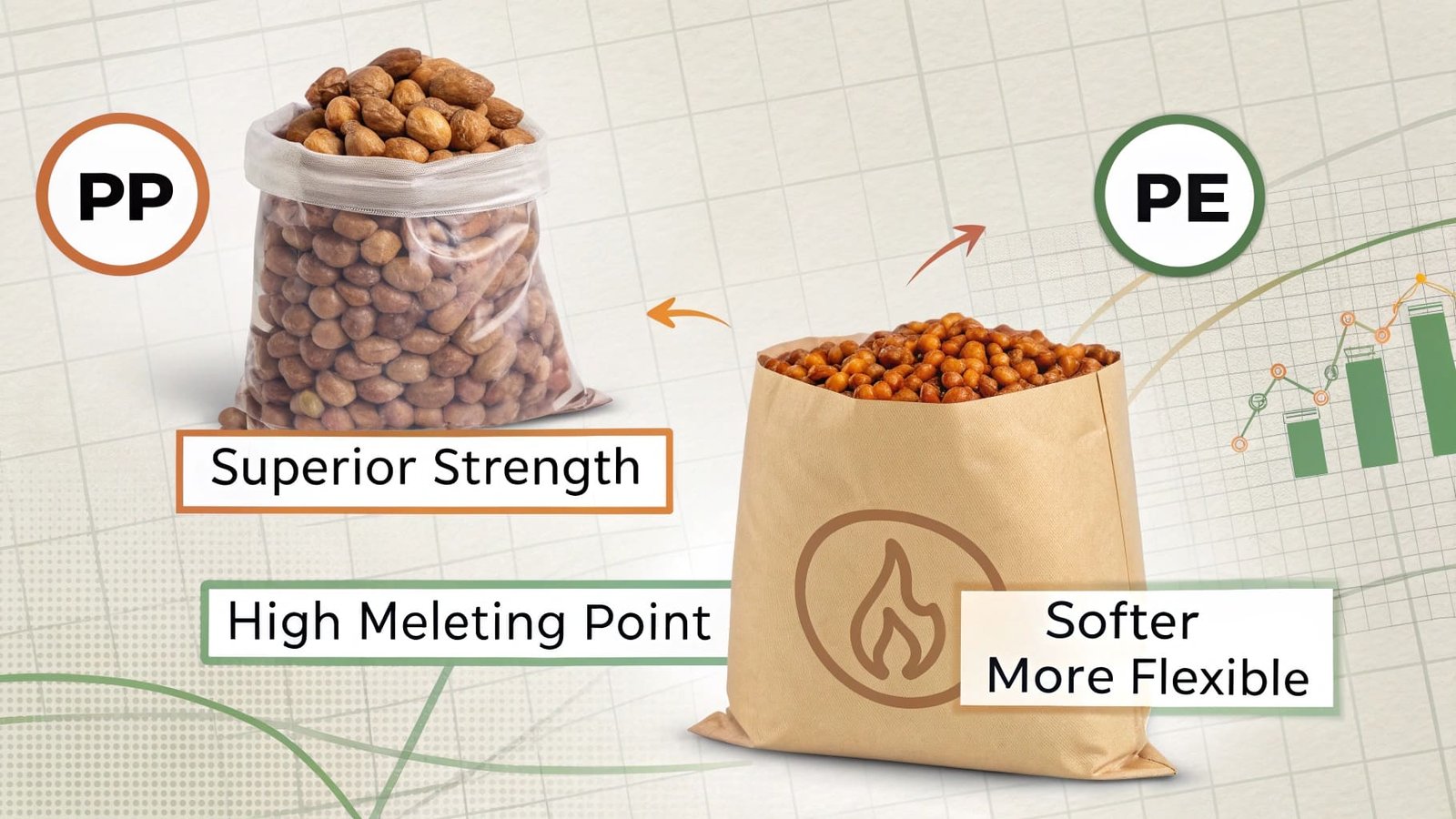

This question is tricky because polypropylene (PP) is a type of plastic. It's better to ask how PP compares to other plastic types. Compared to a standard polyethylene (PE) bag, a PP bag is generally stronger, more rigid, and has better clarity and heat resistance6.

When people say "plastic bag," they often think of the soft, stretchy bags from the grocery store. Those are usually made from polyethylene (PE). Polypropylene is a different polymer with a different set of strengths. I remember a new client who wanted to package hot-roasted nuts. They were using PE bags, and the heat from the nuts was causing the bags to warp and weaken. We switched them to PP bags, which have a much higher melting point. The problem was solved instantly. This experience taught me that saying one plastic is "better" is not helpful. The right question is always: "Which plastic is better for my specific application?" For heat resistance, clarity, and strength, PP is often the superior choice.

Comparing Common Packaging Plastics

To give you a clear picture, let's compare PP to PE, the most common plastic used for bags. Understanding their core differences is essential for a buyer.

Key Performance Indicators

- Strength and Rigidity: PP is much stiffer than PE. This is why it's used for applications that need to hold a shape, like a block bottom bag. PE is soft and flexible.

- Temperature Resistance: PP has a higher melting point (around 160°C or 320°F) compared to PE. This makes it suitable for hot-fill applications or products that might be stored in warm conditions.

- Moisture Barrier: Both are excellent moisture barriers, but PP generally has a slightly lower moisture vapor transmission rate7, which is great for keeping crispy products dry.

- Recyclability: Both PP (Resin ID Code #5) and some types of PE (Resin ID Codes #2 and #4) are recyclable. However, the availability of recycling programs for flexible films can vary widely by region. This is a key point for any company with sustainability goals.

What is a PP pack?

You might hear the term "PP pack" in discussions. This phrase can mean different things, creating potential mix-ups in orders. You need to know what to ask to get the right product.

A "PP pack" is not a standard industry term. It's general slang that could mean a multi-pack of items held together with a PP over-wrap, a single PP bag, or a rigid PP container like a clamshell or tub. To avoid confusion, always specify the exact format you need.

I learned to be very specific about this early on. A new buyer once requested a price for "10,000 PP packs" for their snack bars. One person on my team thought they meant 10,000 small individual bags. Another thought they meant retail-ready multipacks, with 10 bars in each pack. The price difference was huge. I had to call the buyer to clarify. They wanted the multipack wrap film. This taught me a valuable lesson: never assume. Always confirm whether the customer is talking about a bag, a tray, a container, or film wrap. A simple clarifying question can save a lot of time and prevent costly mistakes.

Deciphering the "PP Pack"

Let's look at the most common formats that "PP pack" could refer to. Knowing these will help you pinpoint what your marketing or sales teams are actually asking for.

Flexible Packaging Formats

- Individual Bags: This is a simple bag made from PP or OPP film, sealed on three sides with one open end for filling.

- Shrink Wrap Film: This is PP film used to bundle multiple items together, like a 6-pack of water bottles. The film is wrapped around the products and then heated, causing it to shrink tightly around them.

- Laminated Pouches: High-end packaging often uses a laminate structure, such as PET/OPP. Here, the OPP layer provides the seal strength and moisture barrier.

Rigid Packaging Formats

- Clamshells: These are hinged containers often used for baked goods or salads. They are made from a thicker sheet of PP.

- Tubs and Lids: Think of yogurt cups or margarine tubs. These are formed from PP because it is strong, food-safe, and can be microwaved.

The next time someone on your team asks for a "PP pack," you can guide them to a more precise specification, making your job of sourcing much easier.

Conclusion

Choosing an OPP block bottom bag for chocolates is a strategic decision that enhances product visibility, shelf presence, and freshness, ultimately driving sales and reinforcing your brand's premium quality.

Discover how OPP block bottom bags can enhance your product's presentation and protect its quality. ↩

Explore the importance of moisture protection in maintaining the freshness of your products. ↩

Understand the unique properties of OPP and why it's preferred for premium packaging. ↩

Gain insights into how biaxial orientation enhances the performance of packaging materials. ↩

Find out how tensile strength impacts the durability and reliability of packaging. ↩

Explore the importance of heat resistance in packaging, especially for temperature-sensitive products. ↩

Understand how moisture vapor transmission rate affects product shelf life and quality. ↩